Systems Engineering

Bayly’s Systems Engineering skills and experience has developed in a wide range of fields and disciplines including Defence, Medical and Automotive projects.

|

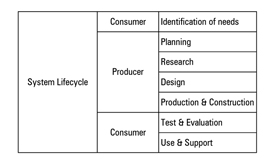

By their nature, product design projects are multi-disciplinary and are all too frequently dogged by problems that threaten their success, lead to poor customer acceptance, and significantly delay the introduction of the product into the market. Systems Engineering is recognized as the best way to manage and control complexity on an engineering level, to avoid problems arising, and where they do arise, limit their impact on the project. Systems Engineering is central to the manner in which Bayly plans and undertakes our product development activities here in Melbourne. Different Standards – same basic process Systems engineering processes are documented in numerous standards and regulatory practices from medical devices (21 CFR Clause 820 / ISO 13485) to a range of national military standards, aerospace and automotive standards. Bayly have experience in specific standards and processes and can adapt their project activities and documentation to suit your requirements. The System Lifecycle System Engineering is best looked at from a lifecycle point of view that considers all the stages from the identification of needs through to the ultimate disposal of the product. Identification of needs Identifying the needs for the product / system is a critical part of every project. Our systems engineering process identifies the importance of the needs as a defined set of requirements included in the design brief or requirements specification for the project. See (link to Research section) for information on the capabilities that Bayly have in Product Design Research. Needs are determined from many sources, from customer wants or desires; the observation of deficiencies or the identification of opportunities in products, systems and services; or from basic research results. Market analysis and segmentation are important activities that allow us to group and catalogue needs for different markets, demographics, users and sections of markets. Consumer Product and B2B Product segmentations are typical product market segmentations that help us consider specific attributes and needs. After considering the needs and determining the opportunities, we are able to identify and document the requirements for the product; define the performance, functions, attributes and operational environment. Different products may be required for different markets. The management of requirements becomes a significant task in very large complex systems. Planning Planning activities merge with the identification of needs and overlap with the Research aspects of the system lifecycle when involving feasibility studies and marketing analysis. More complex systems require advance system planning activities that can include;

Planning also involves establishing manpower plans, finding development, manufacturing and support partners. Bayly is experienced in establishing and implementing plans for systems engineering development. |

The system lifecycle is at the core of systems engineering principles;

|

Research

From a systems engineering perspective, research is a more narrowly defined scope of activities associated with

- basic research – advancing the state of knowledge fields

- applied research – advancing the state of knowledge within specific fields

The methods for conducting the research and the resolution / evolution the research results along commercialisation pathways leading to specific system design and development are the core issues at this stage. Bayly’s team has experience in contributing to the research phase in terms of undertaking applied research activities and managing research activities.

Market and user needs research is considered earlier in the identification of needs.

Design

Bayly’s services, expertise and capabilities are aimed primarily at the design phase of the project.

Design Requirements

Design requirements define the characteristics required of the product and are generally categorised in

- performance requirements – functional; environmental; reliability,

- physical – size; weight; colour,

- test, evaluation and certification requirements

The requirements define how the product will perform, under which conditions the product will perform and how we will prove that the product performs as required.

Bayly is able to assist in the development and specification of the design requirements as required.

Preliminary Design

For complex systems, they need to be broken down into smaller sub-systems layer by layer on a functional or physical basis. The sub-systems inherit the relevant top level requirements in a hierarchical manner and are further defined by their interfaces (physical, electrical and environmental) to the other sub-systems.

Bayly undertakes system design activities to ensure that the overall system compliance will be met from the sub-system performance and interactions. An example may be the breakdown of the overall required weight amongst the sub-systems, or the allocation of a power budget to parts of the system.

The activities of the preliminary design phase include;

- system functional analysis

- breakdown of design requirements

- system optimisation and trade-offs

- system definition and configuration

Detail Design

Simply, these activities are the commonly understood design activities;

- product concept design

- product design development

- prototype design and manufacture

- prototype test and evaluation

The basis for the activities is the design of a product to meet the requirements defined in the requirements specification. Detail design activities are by their nature part of an iterative process and involve cycles of design, prototype and test activities.

We use prototyping as early and as frequently as possible to shorten the timeframe and costs of the detail design phase. Prototyping is the best way to make rapid progress because they are the best way to communicate the functions, feel, features and ideas of a product. We have learnt over hundreds of projects that making prototypes as early as possible in the design of a new product allows us to make the mistakes and the discoveries as early as possible and by doing so, allows us the maximum amount of time to fix the mistakes and to capitalise on the opportunities that are discovered. Models, mockups and prototypes are the best way to change minds and gain acceptance of new ideas. They provide the ideal way to crystallise decisions and get quickly into the hard trade-off choices that are a part of every design project.

For more information of Bayly’s design engineering capabilities see here

Production and Construction

In this phase of the system lifecycle we consider the manufacturing planning, processes and the implementation of these to produce the product. This area has been a focus for the quality improvement imperative that has developed and expanded Worldwide from post war Japan. Quality standards and processes define much of the overall structuring and management of the manufacturing and construction processes. The framework needs to be employed for each new product. In mass manufacturing circumstances, tooling and special purpose machinery is required to control the outcomes of the manufacturing process in a cost effective and reliable manner.

Bayly has experience in the design and manufacture of equipment including

- tooling – injection moulding, die casting, gravity casting, stamping, pressing and forming

- jigs and fixtures – for processing, assembly and inspection

- processing equipment

- automated machinery

For manual and semi-automated manufacturing and construction processes, systems need to be defined and documented in terms of;

- manufacturing flow charts

- process instructions

- inspection instructions

- process design

- product lifecycle data management

- training

An important part of the early stage of manufacturing is the management of the learning curve associated with the establishment of the new product within the manufacturing environment. Bayly focuses on reducing the length and extent of the learning curve so as to meet target costs and other performance criteria as quickly as possible. In order to do this effectively, communication channels need to be established and used to answer queries, provide information and reinforce the product design intent. This reduces scrap, rework and improves the overall efficiency of this phase of the lifecycle.

Test and Evaluation

System Validation

A critical aspect of system engineering is testing the sub-system against the flowed down requirements to ensure that each part of the system will function properly in its role when installed in the larger system. Qualification testing, certification testing, factory acceptance testing and other terms relates to different testing roles but is all testing in a systems engineering context.

System Reliability

In safety critical systems, reliability engineering is of critical importance for mechanical, electrical and software systems. This is a field with specialist requirements that can be added to the Bayly team as required to assist in identifying hazards, assessment of risks and analysing the effects of failures in the system.

Bayly uses standard FMECA processes adapted to suit the particular system based on the International IEC 60812 standard. Bayly can tailor the FMECA / FMEA analysis to suit any specific requirements you may have.

From our many years of experience, FMECA processes work best when applied, updated and continually reviewed throughout the system design process.

Use and Support

In larger, complex systems that are required to run with high reliability and for a long period of time, the logistics of supporting the product are a significant aspect of the project and are managed at all stages of the system lifecycle. The logistics include

- maintenance

- warranty

- training

- repair / replacement

- shelf life management

- re-usable shipping systems

- supply of consumables

- documentation and support

In all cases, the ultimate phasing out, reuse or disposal of the product is a part of the system lifecycle. The trends, especially in the European Community are towards producers taking full responsibility for the disposal of the products.