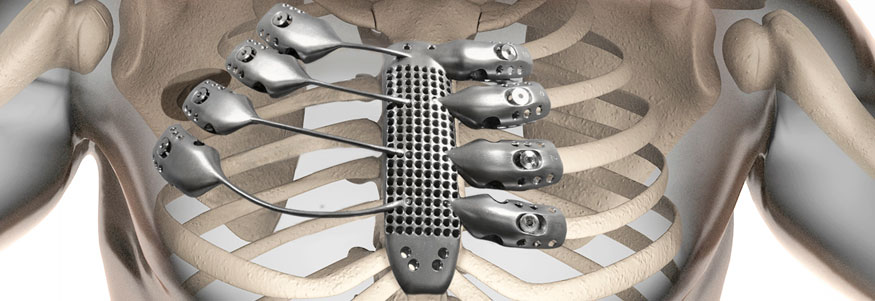

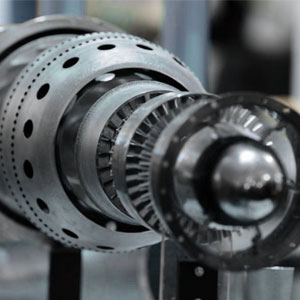

CSIRO's New Metal Printing CapabilityThe rise of 3D printing with plastics has revolutionised Melbourne’s product design and prototyping industry in the last decade. CSIRO’s additive metal manufacturing facility at Lab 22 in Clayton, Victoria is set to deliver the next wave of innovation – Metal 3D printing By developing new material production methods, collaborating on projects and providing facilities to try different 3D printing systems before you buy, CSIRO is breaking down barriers to access new manufacturing technology. Engineers at Bayly Group recently took a tour of Lab 22 and are looking forward to having the opportunity to test its capabilities. Design PotentialCreating parts with fine details, or small intricate structures is much easier using metal 3D printing, allowing existing parts to be redesigned to be much lighter in weight while conserving strength. For example, a solid part with a honeycomb structure inside can be printed. This is not possible using traditional methods. Metal 3D printing is also useful for custom made, or low volume metal parts like prosthetics. The advantages of 3D printing with plastics also apply when working with metals.. New Manufacturing MethodsThis new type of printing uses additive metal manufacturing. This process involves adding material to create a part, rather than removing it, as in traditional metal machining. Metal 3D printing uses a number of different methods. Arcam Electron Beam Melting (EBM) metal 3D printerThe EBM’s powder bed is maintained in a vacuum at a set temperature, keeping the finished part microstructure free from residual stresses and martensitic structures. Standard Arcam supplied titanium alloy, nickel alloys and cobalt chrome are available. These materials are appropriate for orthopedic implants and aerospace applications. The EBM printer’s build envelope (the volume available for part building) is 200 x 200 x 180 mm. Concept Laser LaserCUSING® metal 3D printerThe LaserCUSING® printer specialises in producing high-precision parts. Optomec LENS MR-7 multi-material metal 3D printerThe Optomec printer is especially useful for repairing existing parts, or fabricating high performance parts in single or multiple materials.

If you are interested in the potential of metal 3D printing or have a product that could benefit from the technology then give us a call in Melbourne on (03) 9413 9000, or email Mark at This email address is being protected from spambots. You need JavaScript enabled to view it..

|

A scientist handles a printed 3D object from behind safety glass. This jet engine was produced using metal 3D printing.

|

+61 3 9413 9000