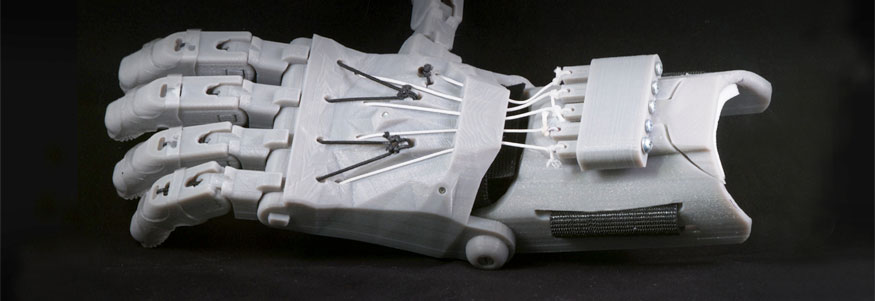

Lending a Hand with 3D PrintingRecently we heard about an organisation providing low cost, 3D printed hand prosthetics and just had to get out there and share e-NABLE’s story! e-NABLE makes their prosthetic hand designs available to everyone to use and manufacture for non-commercial use. Their platform provides all the instructions required to build a hand from customising measurements to assembling the prosthetics and taps into global community of professionals in the design, engineering and medical industry eager to lend a hand. Design ProcessThe technology was co-developed on opposite sides of the world by Ivan Owen and Richard Van As. Richard lost his fingers in a work accident in 2011 and set about researching aid options only to find that prosthetics were not readily affordable. After seeing a video of a functional metal puppet prosthetic made by Ivan, Richard got in touch with Ivan to see if he was interested in developing a replacement finger for injured tradesmen. Ivan was excited by the prospect and their collaboration led to the development of a functional finger prosthetic and eventually a full hand prosthetic for a 5 year old boy in South Africa. Inspiration for the hand prosthetic came from a design archived at the National Library of Australia, developed by Australian dentist Dr Robert Norman. Norman’s prosthetic was built for Corporal John Coles who lost most of his hand in an accident and was made with whale bone and cables. The hand was used for 30 years and gave back some of the mobility John had lost. The prosthetic works by using the movement of another joint, like bending the wrist or elbow to bend the prosthetics fingers. 3D Printing SolutionFollowing the development of the first hand prosthetic Ivan realised that children would rapidly outgrow their prosthetics and would require constant upgrades. While 3D printing doesn’t offer the quality of other prototyping methods, it certainly offers a cost effective solution for customisable, replaceable parts needed by fast growing kids with a variety of limb differences. You can get involved in the e-NABLE community here. We are really excited about this work and will definitely keep following the project! If you would like to know more about the useful applications of 3D printing or open-source technology contact our Melbourne Product Design team today at This email address is being protected from spambots. You need JavaScript enabled to view it. or give us a call on +61 3 9413 9000. We’d love to chat! Don't miss out. Sign up for our newsletter now!

|

Cam's Robot Hand Nicol's Frozen themed arm All images: e-NABLE |

+61 3 9413 9000